backorder

How to effectively manage backorder with no stress?

Your distributor placed an order for many of your products and expected the goods to be delivered on time.

You place the orders with the factory and were informed that a number of the products cannot be delivered on time. New delivery dates were given to you by the factory for a number of items. The complication increased when the same product cannot be delivered all at one go. It had to be split into multiple delivery dates.

You need to communicate the new delivery dates to the distributor.

Things would have been easy if you were just working with only one distributor. There were other distributors and the same problem existed for them too.

Managing backorder is not a simple task when there are multiple distributors and multiple delays for the goods. You need to refer to the distributor order and compare it with the factory order. It is not an easy job because there are many line items to work on. And you need to keep the distributors updated if there are even more delays.

That’s what one of my participants in corporate customer service faced. And she does not have a better way to manage the 2 lists other than putting them side by side as she talks to the distributor.

She wishes that there is a way for her to see the customers, the goods, the requested delivery dates and the expected delivery dates all in one screen.

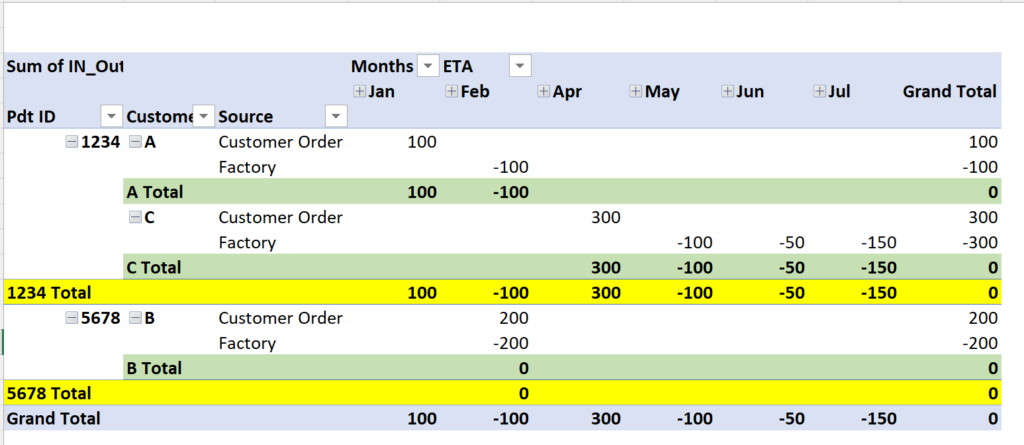

I took the whole problem and came out with this:

- Stack the 2 worksheets (all distributors and factory orders) vertically.

- Change the quantity for the factory delivery to negative.

- Create a Pivot Table and present the distributors and the products in rows.

- Put the monthly date in columns and

- Put the quantities for factory and distributors into the summation value box.

- This is what I gave her

Hopefully, I believe it solves her problem.

If you want to learn how to make your job easy with Excel, Business Analytics or Power BI, check out our courses here https://www.everydayexcel.com/excel-courses/